Benefits and unique advantages of the Olds Elevator

- Vertical or inclined transfer silently and dust is virtually eliminated

- Provides an inherent explosion barrier or choke due to its full-bore mode that will prevent explosions or deflagrations propagating to other parts of the plant.

- Unique design avoids the high-risk ignition sources that can occur inside conventional elevators, especially bucket elevators.

- Flow of material is always smooth and steady, without the pulsations experienced with conventional screw conveyors and bucket elevators.

- Any fine particles (dust) are contained in the full-bore mode of flow

"I see the Olds Elevator replacing lots of bucket elevators," - Associate Professor Peter Wypych,

- Zero to minimal product damage

- Handles slurries and pastes

- Quite, energy-efficient and occupies minimal floor space

- The pick up height is at the lowest point of the elevator, and can be at virtually floor level.

- The transfer rate is volumetrically proportional to speed, so the machine can be used as a variable rate feeder.

“Performance is more predictable, more reliable, more product friendly, more product tolerant and much less maintenance prone than conventional elevators.”

- Feed material can be entered from any sector of the machine's pick up point.

- As the discharge end has no bearings, seals or a drive, discharge can be close to the ultimate headroom.

- The discharge can be divided into two or more sectors.

- Bearings are totally external to the product flow and accessible for maintenance.

- The drive can be located at any position on the housing, to suit easy mounting, wiring and access

"What a unique device this is. Imagine replacing a bucket elevator with something that won't break down, is unaffected by material temperature, can handle wet or damp product and only has one moving part... brilliant, read on!" - Joe Taylor, Editor of www.powderandbulk.com

Advantages over conventional screw elevators

- Higher output.

- Dust is virtually eliminated

- Can be used to control the rate of feed.

- Gentler handling.

- Lower pick up/larger hopper capacity.

"Quite simply, it will perform the duty that other screw elevators won't." - Mr Lyn Bates, Ajax Equipment Ltd, England.

- No seal leakage or bearings exposed to product.

- Lower Maintenance.

- Easier to access drive assembly.

- No product segregation.

- Very high turn down rate

“Safer than other elevators because it will prevent explosions or deflagrations propagating to other parts of the plant.”

- No contact between screw and casing.

- Deals easier with poor flowing products.

- More uniform discharge.

- Simultaneous heating or cooling of product.

- Rapid cleanout for product changeovers.

“Wide uses in the processing of foods, chemicals, minerals. Process engineers now have an efficient new tool with very high levels of safety.”

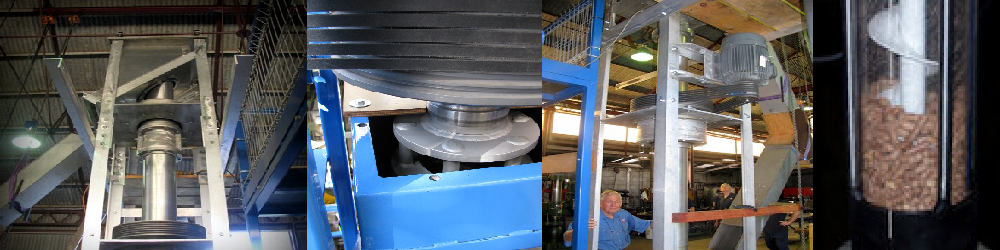

This innovative development improves plant safety and enlarges the scope for elevating bulk solids by overcoming many of the drawbacks and limitations of conventional machines. Olds Elevators are available in Mild or Stainless Steel with a wide range of surface finishes. Sizes range are from 75 to 610 mm diameter, larger units can be produced if required.

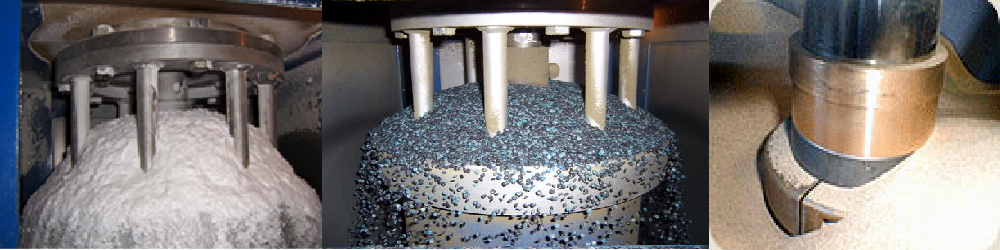

Dust Control

Olds elevators control dust inherently. That is, its operating principle prevents the generation of dust during elevation. Since the elevator delivers its materials in fully-flooded mode there is insufficient air for dust to form. The only air in the elevator is the interstitial air between the individual particles.

Even if the material is comprised of dust-sized particles there will be no dust elevated because there is no air for the dust particles to be suspended in. When an Olds elevator is stopped the casing remains completely full of product. There is no fall back to fill in air voids as there are no air voids in the casing.

We would like to work in partnership through licensing this technological breakthrough to you. Enquiries about manufacturing this new technology under licence are welcome.